Auto buffing and polishing are meticulous restoration processes that transform a car's exterior by removing scratches and imperfections, achieving a smooth, glossy finish. Professionals use various techniques from hand-buffing to machine polishers for aesthetic enhancement and long-term paintwork protection. Safety is paramount in auto buffing shops, with comprehensive measures including staff training, protective gear, regular equipment inspections, and well-maintained ventilation systems. Best practices prioritize staff safety through chemical handling training, machine maintenance, clear protocols, organized workspaces, and supervisor inspections.

In today’s digital era, auto buffing and polishing have evolved into essential services for vehicle owners seeking a flawless finish. Understanding these processes is crucial for shops aiming to provide top-notch auto care. This article delves into the safety measures and best practices that shops implement during auto buffing and polishing to protect both customers and employees. By adhering to stringent protocols, they ensure a secure environment while delivering exceptional results.

- Understanding Auto Buffing and Polishing Processes

- Safety Measures in Shops for Auto Care

- Best Practices for Ensuring Customer and Employee Safety During Auto Buffing and Polishing

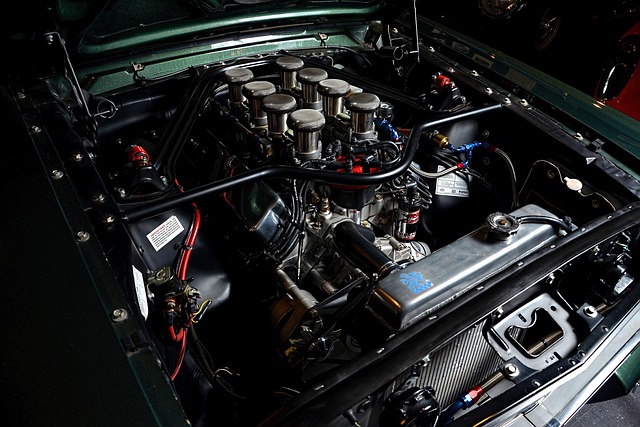

Understanding Auto Buffing and Polishing Processes

Auto buffing and polishing are meticulous processes that transform a car’s exterior, revealing its true potential. It involves using specialized machinery and chemicals to remove minor scratches, swirls, and imperfections from the paintwork, resulting in a smooth, glossy finish. This process not only enhances the car’s aesthetic appeal but also protects its surface by sealing and rejuvenating the paint. In an auto body shop, buffing and polishing are crucial steps in car body restoration, ensuring that each vehicle leaves the facility looking as good as new.

Understanding these processes is essential for any owner seeking to maintain or restore their vehicle. Auto body repair professionals employ various techniques, from hand-buffing with pads and compounds to using advanced machine polishers, depending on the extent of damage. The goal is not just to improve visual appeal but also to protect the car’s investment by preventing further damage from environmental factors and everyday wear and tear.

Safety Measures in Shops for Auto Care

Shops specializing in auto buffing and polishing take safety seriously, implementing robust measures to protect both employees and vehicles. Beyond basic training for staff on safe handling procedures, these shops are equipped with specialized tools designed to minimize risk. Safety gear like gloves, goggles, and masks are universally required, preventing exposure to chemicals and airborne debris common during auto body work and polishing processes. Moreover, well-maintained ventilation systems ensure proper air circulation, eliminating potential hazards from fumes and dust. Regular inspections of equipment and facilities further safeguard against accidents and maintain the highest standards in automotive body shops.

Best Practices for Ensuring Customer and Employee Safety During Auto Buffing and Polishing

To ensure safety during auto buffing and polishing, shops should adopt best practices that protect both customers and employees. First, all staff involved in auto buffing and polishing must be adequately trained on proper use of equipment and handling of chemicals. Protective gear, including gloves, goggles, and respirators, is essential to prevent skin irritation, chemical splashes, and inhalation of fumes. Regular maintenance and calibration of buffing machines are crucial to ensure they operate safely and efficiently, minimizing the risk of accidents or damage to vehicles.

Additionally, shops should establish clear safety protocols for auto frame repair and car paint repair processes that are closely followed during auto buffing and polishing. This includes proper ventilation to reduce exposure to volatile organic compounds (VOCs) from paints and solvents. Implementing a well-organized workspace, keeping tools and materials in designated areas, and maintaining a clean environment further enhances safety. Regular inspections of the work area by supervisors can help identify potential hazards and ensure compliance with safety standards, making auto buffing and polishing procedures safer for all involved.

Auto buffing and polishing are essential processes that require careful attention to safety. By implementing robust safety measures, shops ensure customer and employee protection throughout these procedures. Best practices include proper training, using personal protective equipment (PPE), maintaining well-ventilated spaces, and adhering to strict protocol for handling chemicals and machinery. These comprehensive strategies not only safeguard individuals but also contribute to high-quality auto care outcomes, fostering customer confidence in shop services.